Introduction: why surge protection testing matters

Surge Protection Devices (SPDs) play a vital role in shielding electrical systems from voltage spikes caused by lightning strikes, switching operations, and other transient events. Over time, however, these devices can degrade—rendering them ineffective without any visible signs of failure. That’s why SPD testing and regular surge protection device testing are critical for ensuring continued safety and reliability.

Many facilities install SPDs and forget about them, assuming they're a one-time investment. But without a proper surge protection test, it's impossible to confirm whether the unit is still functioning as designed. Failure to do so can lead to equipment damage, data loss, or even downtime in industrial settings.

In this article, we’ll walk you through how to test a surge protector, the types of SPD testers used, and how to identify a failing device before it’s too late. Whether you're an electrical engineer, maintenance technician, or facility manager, understanding the SPD testing procedure is essential for preventive maintenance and risk mitigation.

Let’s begin with the tools you’ll need before diving into surge protector testing methods.

Surge protection device test equipment

To carry out effective SPD testing, you need the right tools. Several types of surge protection device testers are available on the market—ranging from simple multimeters to specialized SPD analyzers designed for compliance with IEC 61643 standards.

The most commonly used tools include:

● Multimeter: A digital multimeter is the most basic tool available and is commonly used for initial checks. It can verify circuit continuity, measure resistance, and—when used carefully under the right conditions—check for abnormal voltage levels across surge protection terminals. While a multimeter cannot simulate surge events or assess the SPD's dynamic response, it can help identify visible signs of failure, such as a shorted or open MOV.

Figure 1 - Versatile multimeter tester

● Insulation Resistance Tester: Often referred to as a “megohmmeter,” is primarily used to assess the integrity of insulation within the SPD and its connected wiring. By applying a high DC voltage (typically 500V or 1000V), it measures the resistance of insulation materials. Low insulation resistance may indicate internal degradation or moisture ingress—conditions that compromise SPD safety and performance.

Figure 2 - Insulation Resistance Tester

● Portable SPD Testers: They are dedicated instruments designed specifically for surge protection device testing. Unlike general-purpose tools, portable SPD testers can evaluate parameters such as clamping voltage, leakage current, and response degradation. Some models can detect whether the internal components (e.g., MOVs, gas discharge tubes) are still within safe operational limits. These testers often provide go/no-go indicators or digital readouts, making them especially useful for field technicians performing compliance or routine maintenance inspections.

Figure 3 - Surge protection device tester

When choosing test equipment, consider the SPD type (Type 1, Type 2, or Type 3), its location (main panel vs. Do wnstream), and whether the test will be online (without disconnection) or offline (with device isolation). For example, a surge protection device SPD tester may be preferable in industrial settings where comprehensive diagnostics are necessary.

Regular use of proper test instruments ensures surge protection testing is both accurate and safe. Moreover, recording test results over time can help track device degradation trends—an important part of any preventative maintenance plan.

|

Equipment |

Use Case |

Key Metrics |

Limitations |

|

Multimeter |

Basic continuity & voltage check |

Resistance, DC voltage |

Cannot simulate surges; low accuracy |

|

Insulation Tester |

Insulation status assessment |

Insulation resistance (MΩ) |

General-purpose; not SPD-specific |

|

Portable SPD Tester |

Field testing of SPDs |

Clamping voltage, leakage |

Expensive; may need technical training |

Table 1 - Surge Protection Device Test Equipment

How to test a surge protector with multimeter

A digital multimeter offers a simple way to perform preliminary testing on a surge protector, especially in the absence of specialized SPD testers. Although it cannot replicate the conditions of a transient overvoltage or lightning strike, it can still provide helpful insights into whether an SPD is visibly damaged or has failed internally.

One basic method is to test the resistance across the surge protector’s terminals. First, unplug the device and set the multimeter to the resistance (Ω) or continuity mode. Measure the resistance between the line and neutral, as well as between the line and ground. A functioning surge protector will typically show high resistance or display "OL" (open loop). If the reading is close to zero, it may indicate a shorted metal oxide varistor (MOV), suggesting failure.

In the absence of professional testing equipment, another approach is the voltage drop method. To perform this, turn the multimeter’s knob to the DC voltage range. Connect the red probe to the positive electrode of the surge protector and the black probe to the negative electrode. Then, turn on the power and observe the multimeter’s reading. If the display shows 0V, the surge protector is likely operating normally. However, if the reading is not zero, this could mean the SPD has failed.

It's important to note that this method provides only a rough indication. Surge protectors are designed to respond to high-energy events such as direct lightning strikes or induced surges, conditions that a conventional multimeter cannot simulate. Therefore, multimeter testing should be treated as a reference only, not a definitive diagnostic. Additionally, extreme caution must be taken during live voltage testing to avoid electric shock or arcing. Ensure the multimeter is set to the correct range, and never attempt this procedure without adequate knowledge and safety measures in place.

How do i know if my surge protectors is bad?

SPDs often fail silently—making it difficult to know when replacement is needed without proactive testing. So how do you know if your surge protector is bad?

Here are common warning signs:

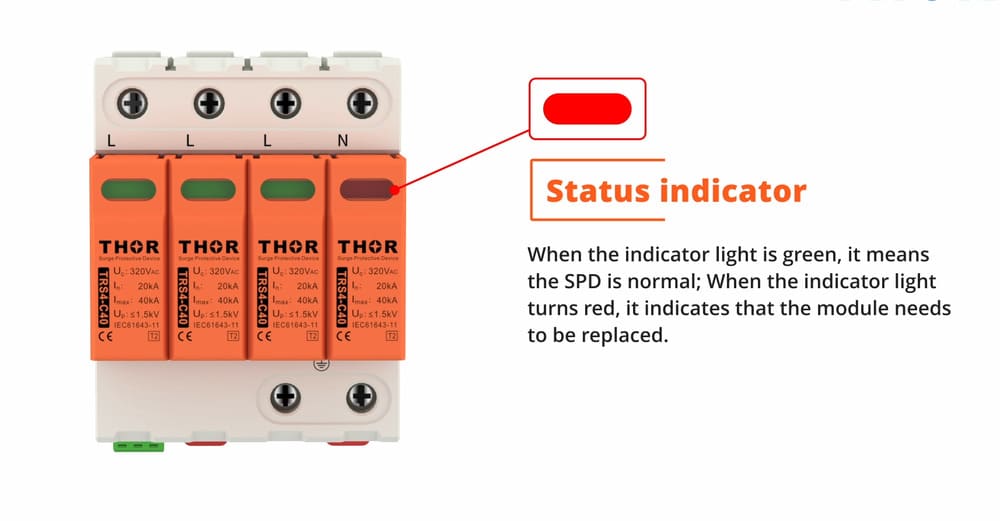

● No Status Indicator: Most SPDs have an LED or visual flag; If the indicator window on the SPD turns red, the unit may be compromised.

● Frequent Power Issues: Unexplained equipment malfunctions or resets could indicate degraded surge protection.

● Burn Marks or Unusual Odor: Physical damage is a strong indicator of failure.

● Buzzing Sound: Internal damage may cause audible noise, especially during load spikes.

● Failed Multimeter Test: If resistance readings are off, the MOVs could be shorted or open.

In high-risk environments, routine surge protection testing should be scheduled to catch these issues early. If you’re unsure, consult an electrician or use a surge protection device SPD tester to verify functionality.

Failure to replace a compromised SPD leaves your equipment vulnerable to the very surges it was designed to block. In other words, if you don’t check your surge protection device, it may not be there when you need it most.

SPD maintenance and replacement

Routine maintenance and timely replacement are key aspects of any SPD testing procedure. Like fuses or filters, SPDs are consumable components—they don’t last forever.

Maintenance tips:

● Visual Inspection: Look for status lights, discoloration, or melted parts.

Figure 5 - Built-in status indicator

● Scheduled Testing: Perform surge protector tests annually or after major storm events.

● Keep a Log: Track installation date, test results, and replacement history.

When to Replace:

After any major overvoltage event (e.g., lightning strike).

When test results show deteriorated MOV performance.

If the status indicator is non-functional or shows failure.

If the SPD tester or multimeter reveals abnormal readings.

Replacing an SPD before it fails ensures continued protection of critical systems. Many facility managers now include SPD maintenance in preventive maintenance checklists, alongside breakers and insulation resistance tests.

In mission-critical applications—like telecom, hospitals, or industrial control panels—it's often better to replace SPDs preemptively than wait for failure. With proper surge protection device testing, you can make informed decisions and avoid costly surprises.

Standards and Regulations for SPD Testing

Surge Protection Devices (SPDs) must comply with international and national standards to ensure safety, performance, and reliability. Understanding these SPD testing standards is essential for facility managers, engineers, and OEMs who are responsible for maintaining electrical system integrity.

The most widely referenced standards include:

IEC 61643 Series:

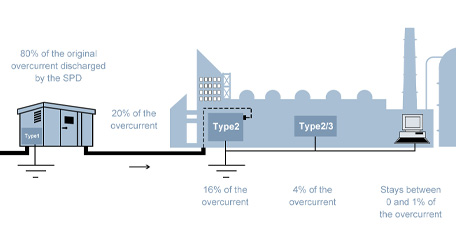

Outlines the international guidelines for classifying SPDs into Type 1, Type 2, and Type 3, based on installation location and expected surge exposure. The standard specifies test methods such as impulse current testing, voltage protection level measurement, and thermal stability checks. It serves as the foundational reference for SPD design, manufacturing, and testing across most global markets.

UL 1449 (North America):

Defines SPD safety requirements in the United States, with a strong emphasis on fire hazard reduction and personal protection. Devices are tested under high-energy surge simulations to assess performance, including let-through voltage limitations. Meeting UL 1449 is essential for product certification and market access in the U.S.

GB/T 18802 (China):

Adopts many core principles from IEC 61643 but adapts them to Chinese grid characteristics and regulatory needs. The standard includes detailed procedures for performance testing, installation guidance, and lifecycle maintenance, ensuring SPDs used in China meet both safety and operational benchmarks.

|

Standard |

Region |

Scope |

Key Testing Criteria |

|

IEC 61643 Series |

International |

SPD types, classification, test methods |

Impulse current, voltage protection, thermal tests |

|

UL 1449 |

United States |

Safety and fire prevention in SPD design |

Let-through voltage, surge simulation, durability |

|

GB/T 18802 |

China |

Local adaptation of IEC for China’s grid |

Performance test, maintenance guidance |

Table 2 - Standards and Regulations for SPD Testing

Testing to standard not only improves equipment longevity but also supports insurance claims and audit readiness. If your SPD is part of a certified system, using unapproved SPD testers or skipping regulated test intervals could void warranties or expose the system to legal risk.

Conclusion

Proper surge protection starts with knowing how to test surge protection devices effectively and in compliance with established standards. Whether you're conducting a quick multimeter check or using a dedicated SPD tester, each step plays a role in ensuring your electrical systems remain protected from transient overvoltages.

We’ve covered the essentials—from selecting the right surge protection device test equipment to understanding telltale signs of a bad surge protector. You’ve also learned how to carry out basic surge protection tests, interpret results, and recognize when it’s time for maintenance or replacement.

Crucially, testing procedures should align with internationally recognized standards like IEC 61643 and UL 1449, which define the minimum acceptable safety and performance benchmarks for SPDs. Adhering to these regulations doesn’t just keep your systems safe—it also supports compliance, insurance coverage, and long-term equipment reliability.

By integrating routine SPD testing procedures into your maintenance schedule and staying informed on compliance requirements, you can prevent costly equipment failures and unplanned downtime.

In short, don’t treat surge protectors as “install-and-forget” devices. Regular inspection, testing, and standard-compliant verification are your best defenses against hidden risks in modern electrical systems.