Surge protection devices (SPDs) are vital in protecting electrical systems from voltage spikes and transient surges, ensuring operational continuity and safety. Regular surge protection device maintenance maximizes their effectiveness, safeguarding critical infrastructure and equipment against potential damage and downtime.

Introduction: why surge protector maintenance is essential

Surge protection devices are installed to absorb or divert excess voltage caused by lightning strikes, power grid fluctuations, or internal switching operations. While these devices are designed to act quickly and repeatedly, their protective capabilities degrade over time—sometimes silently. A lack of regular maintenance of SPD can result in catastrophic system failures, costly downtime, and potential safety hazards. Integrating routine surge protection device maintenance into an electrical safety strategy is therefore not just good practice—it is essential.

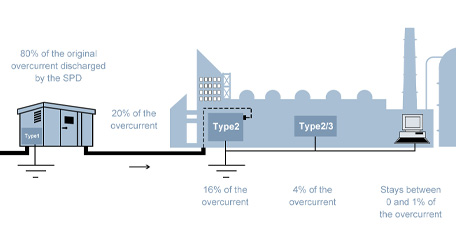

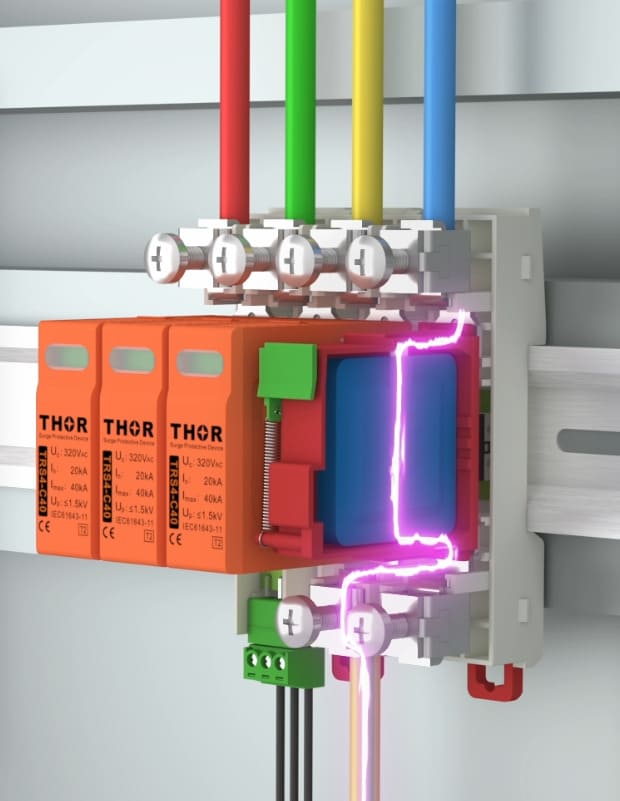

Figure 1 - Internal Arcing Fault Demonstration in SPD Module

SPDs are especially critical in modern infrastructures where even a minor surge can disrupt communication systems, data centers, smart building controls, and factory automation lines. The financial losses from damaged electronics often far exceed the investment required for maintaining protection systems. Regular SPD inspections and timely replacements form a key part of preventive maintenance programs.

How surge protection devices work & when they wear out

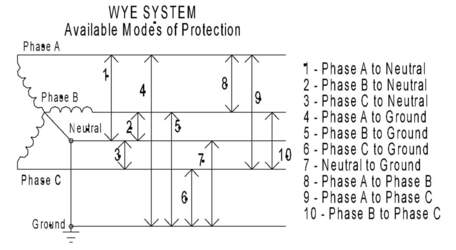

SPDs work by limiting transient voltages by diverting surge current away from sensitive components. The most common types of internal components include Metal Oxide Varistors (MOVs), gas discharge tubes (GDTs), and silicon avalanche diodes. Over time, these components degrade with each surge event.

What is the lifespan of a surge protector?

The typical lifespan of an SPD is 5–10 years.

Factors such as environmental conditions, number and intensity of surge events, and the quality of the SPD all impact service life.

Indicators of aging include non-functional status LEDs, lack of response during surge testing, or evidence of physical damage. Surge protection device maintenance helps detect these issues before they result in equipment failure.

MOV-based SPDs, which dominate the commercial market, degrade gradually and are particularly susceptible to cumulative exposure. Even if no major surge has occurred, constant minor surges can cause a slow decline in performance.

How to tell if your surge protector is failing

An SPD does not always show visible signs when it loses functionality, but there are several ways to determine failure:

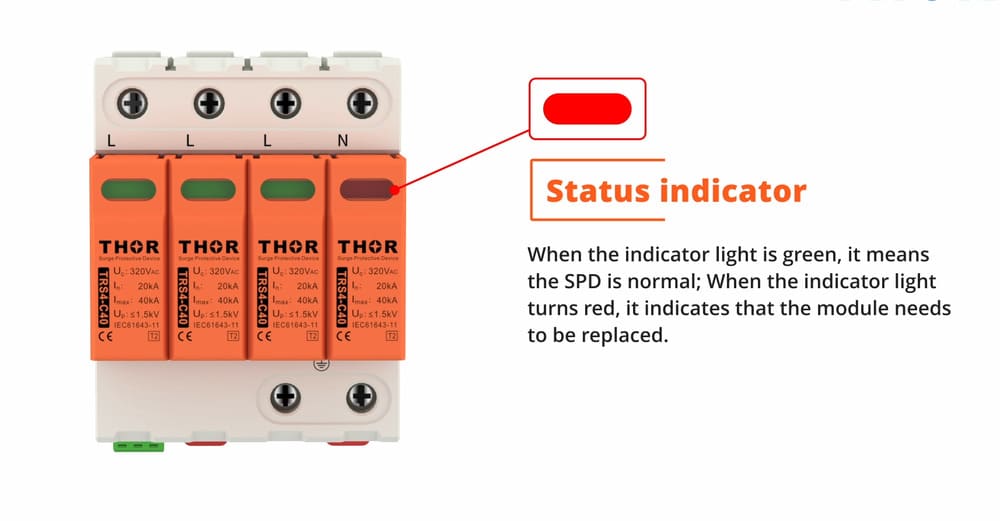

● Status Indicators: Most modern SPDs feature LED indicators. A green light usually indicates the device is functional, while red or no light indicates the unit has failed or requires attention.

Figure 2 - Built in SPD status indicator

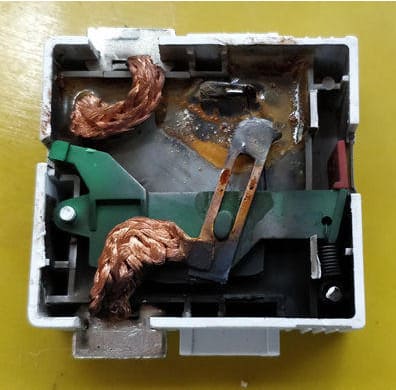

● Visible Damage: Burn marks, cracked housings, melted terminals, or corrosion are all warning signs that an SPD is no longer safe or effective.

Figure 3 - Severe SPD damage after major surge event

● System Performance: Repeated issues like unexplained reboots, communication errors, or equipment resets can indicate a failed SPD.

● After Major Events: Any time a significant surge (e.g., lightning) is detected by a surge counter or system event log, the SPD should be inspected or replaced.

In some cases, thermal disconnects in the SPD may activate, which silently removes protection. Without regular testing or status monitoring, facilities might not realize protection has been lost until equipment fails.

Inspection and maintenance frequency

How often should surge protection be checked? That depends on the environment and criticality of the protected systems. Recommended intervals:

● Monthly: Visual inspections for status lights, physical integrity, and connection security.

● Quarterly: Internal panel inspections for terminal torque, ground integrity, and signs of overheating.

● Annually: Comprehensive tests using surge protection testers, insulation resistance meters, or thermal imaging.

In high-risk environments (e.g., data centers, industrial plants, areas with high lightning density), surge protection device maintenance may need to be more frequent. Maintenance schedules should be customized based on risk assessments and manufacturer recommendations.

Some advanced facilities integrate SPD checks into their Building Management Systems (BMS) or SCADA platforms, allowing real-time monitoring of protection health.

Performance monitoring and testing

Surge protection device maintenance includes various types of performance verification:

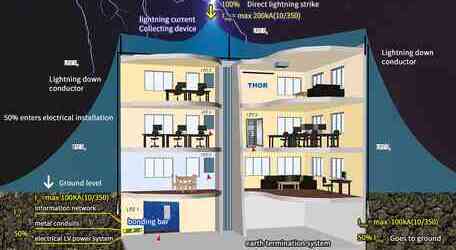

Surge Counters: Some Type 1 and Type 2 SPDs come with integrated surge counters. Tracking the number and intensity of surge events helps assess remaining lifespan.

● SPD Testers: Portable SPD testers simulate surge events to measure whether the device responds within specification.

When testing a surge protective device (SPD) with a multimeter, we typically check both voltage and resistance to assess its operational status.

In the case below in Figure 4, for voltage testing, a measured value of approximately 385V between two phase lines in a 380V system indicates normal operation within the acceptable fluctuation range. For resistance testing under live conditions, an infinite (open circuit) reading between the neutral (N) and ground (PE) terminals means the SPD’s internal components—such as metal oxide varistors (MOVs)—are in their normal, non-conductive state, suggesting no surge has occurred.

In the case below, both readings confirm that the SPD is functioning correctly and has not been triggered or degraded.

|

|

Figure 4 - Using multimeter to test surge protection devices

● Insulation Resistance Testing: Identifies breakdown in protective circuits or signs of moisture intrusion.

● Clamp Voltage Testing: In lab conditions, checking whether the device clamps at the correct voltage is a precise method to validate performance.

Figure 5 - Semi-automatic inspection pressure sensitive tester

Periodic testing ensures SPDs remain within operational parameters and provides evidence of preventive maintenance. It also helps justify replacements before failure occurs.

Criteria for SPD replacement

Surge protectors are not infinite-use devices. SPD maintenance should always include an evaluation against defined replacement criteria:

● End Of Service Life: Replace according to manufacturer guidelines or after maximum surge count.

● Degraded Indicators: A non-functional status LED or known surge impact should prompt immediate replacement.

● Post-Incident Check: After lightning strikes or utility power disturbances, replacement is often safer than testing.

● Routine Upgrades: When older SPDs no longer meet updated standards (UL 1449, IEC 61643), consider proactive upgrades.

Some facilities keep spare SPDs in inventory to allow immediate replacements. This minimizes downtime and avoids the lead time involved in sourcing new units.

Maintenance best practices and safety guidelines

Effective surge protection device maintenance requires procedural discipline:

Lockout/Tagout: Always isolate power before inspection or replacement.

Qualified Personnel: Technicians should be trained to recognize SPD types, wiring configurations, and hazards.

Tools and PPE: Use certified testing equipment and always wear appropriate protective gear.

Documentation: Maintain logs of inspections, test results, replacements, and surge events.

Additional best practices include:

Installing SPDs with remote signaling for BMS integration

Using thermal imaging to detect loose connections or overheating

Reviewing historical event logs to optimize maintenance intervals

|

Frequency |

Task |

Performed By |

|

Monthly |

Visual inspection (LED, terminals) |

Electrician |

|

Quarterly |

Connection and torque check |

Maintenance Team |

|

Annually |

Surge counter review, IR testing |

Certified Technician |

|

After Surge |

Replacement or performance re-test |

Technician |

Table 1 - Conclusion and maintenance schedule template

Surge protection device maintenance is a key component of any facility's electrical reliability strategy. It ensures uninterrupted protection for sensitive equipment, minimizes operational risk, and supports compliance with international standards.

By adhering to structured inspection schedules and replacing SPDs as needed, facilities can maintain resilience against power disturbances. In a world increasingly reliant on sensitive electronics and automation, proactive SPD maintenance is not just a best practice—it’s a necessity.