In the journey of industrial manufacturing, the shift in production methodologies often symbolizes technological advancement and enhanced market competitiveness. Thor, a leading surge protective device (SPD) manufacturer with nearly two decades of expertise, has significantly evolved from manual production methods toward advanced automated manufacturing. This transformation has not only elevated efficiency and product consistency but has also reinforced Thor's competitive edge in quality control, cost management, and rapid market responsiveness.

1. Thor's Journey: Two Decades of Excellence

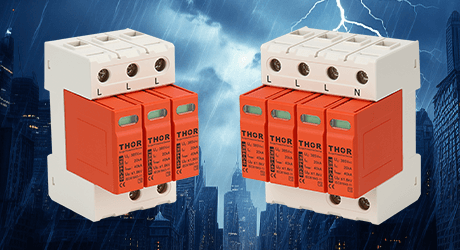

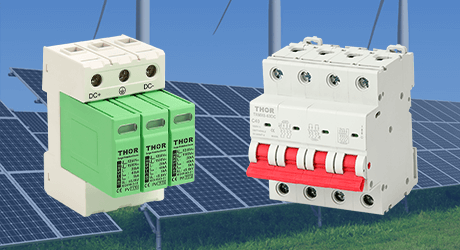

Since its founding in 2006, Thor has consistently focused on the research and manufacturing of surge protective devices, evolving comprehensively through defined stages:

Startup Stage (2006-2012): Manual Foundation

● Initial production heavily reliant on manual labor, cultivating a team of highly skilled technicians.

● Rigorous quality control established Thor's initial market reputation.

● Products strategically targeted towards international markets from inception.

Growth Stage (2012-2018): Technological Accumulation and Innovation

● Introduction of basic automation like automatic dispensing and semi-automated testing equipment.

● Obtained ISO 9001 certification.

|

|

● Expanded product portfolio significantly.

● Established an in-house laboratory dedicated to low-voltage surge protective device testing.

● Increased annual production capacities significantly, stabilizing international exports.

Upgrade Stage (2019-Present): Automation Transformation

● Extensive adoption of automation technologies including robotic soldering and packaging systems.

● Plans initiated for comprehensive automated assembly lines.

● Modernized testing laboratories conforming to RoHS guidelines, achieving international certifications such as TUV and CE.

● Enhanced market presence, particularly in Asia and Europe.

Future Planning (From late 2025): Comprehensive Automation Advancement

● Established strategic partnerships with domestic automation solution providers.

● Planned construction of Thor's first fully automated production line.

● Expected significant increase in production capacity and quality consistency.

Continuous innovation in manufacturing processes remains central to Thor's sustained growth and industry leadership.

2. Limitations of Traditional Manual Production

Early SPD manufacturing at Thor relied extensively on manual processes. Despite initial success, manual production gradually faced notable constraints:

● Limited Efficiency:

Time-consuming manual assembly and soldering constrained the ability to fulfill large-scale orders efficiently, creating bottlenecks during peak periods.

● Inconsistent Quality:

Human error and variations inevitably led to inconsistencies in product quality, potentially affecting market reputation.

● Rising Labor Costs:

Growing labor expenses posed significant challenges, increasing operational costs.

● Challenges in Adapting to Industry Standards:

Evolving standards from bodies like IEC necessitated precision and consistency difficult to achieve through manual labor alone.

3. Advantages of Automation: Thor's Practical Implementation

Thor has progressively adopted automation, integrating human-machine collaboration to maintain operational flexibility while enhancing precision and productivity:

● Enhanced Efficiency and Shorter Delivery Cycles:

Automated soldering and assembly significantly reduced production time, increasing efficiency by more than 30%.

Standardized processes reduced human intervention, ensuring timely order fulfillment.

● Improved Product Consistency and Reliability:

Precision automated machinery accurately managed critical manufacturing parameters, significantly reducing variability.

Automated testing equipment improved reliability through accurate detection of key performance indicators.

● Reduced Costs and Strengthened Competitiveness:

Decreased reliance on labor reduced long-term operational costs.

Precise automation improved raw material usage efficiency and lowered wastage rates.

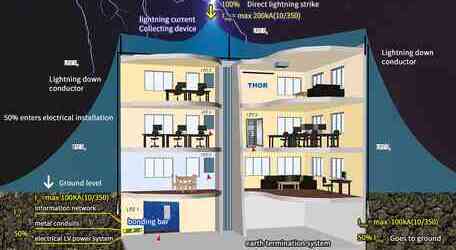

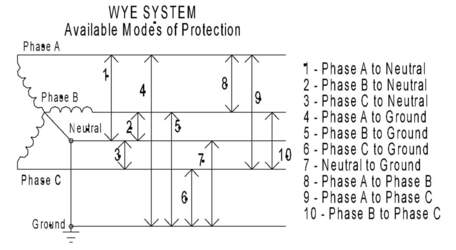

● Compliance with Industry Standards and Enhanced Brand Image:

Easier compliance with international standards such as IEC 61643 and UL 1449.

Modern production practices strengthened customer trust and market credibility.

4.Future Outlook of Automated Manufacturing at Thor

Ⅰ. Transition to Full Automation

Thor is strategically moving toward complete automation to further streamline production efficiency and enhance product consistency. Building upon existing semi-automated processes, the next critical step involves the integration of comprehensive automated production lines capable of handling all stages—from raw material processing to final product assembly—without manual intervention. The introduction of fully automated conveyor systems, advanced robotic manipulators, and precision assembly robots will significantly boost production rates, achieving at least double the current manufacturing capacity. This shift not only improves throughput but also substantially reduces variability inherent in manual operations, leading to exceptional quality standards and consistency, crucial in meeting increasingly stringent global market demands.

Ⅱ. Integration of Industrial Internet of Things (IIoT)

To maximize the benefits of automation, Thor plans to deeply integrate Industrial Internet of Things (IIoT) technologies into its production environment. By embedding smart sensors throughout the production equipment, Thor will enable real-time monitoring and data collection across all production stages. The detailed, real-time data capture allows for predictive maintenance, swiftly identifying potential issues before they escalate, thereby significantly minimizing downtime. The integration of IIoT not only ensures higher operational efficiency but also provides transparent traceability of products, enhancing quality assurance practices. Moreover, with interconnected IIoT systems, Thor will gain powerful analytics capabilities, enabling data-driven decision-making to optimize production processes continually.

Ⅲ. Optimization through Artificial Intelligence (AI)

Leveraging artificial intelligence (AI) represents the next frontier in Thor's manufacturing evolution. AI-driven systems will analyze massive volumes of production data collected via IIoT sensors to identify patterns and predict optimal operating parameters. By employing machine learning algorithms, Thor aims to continuously fine-tune manufacturing processes, achieving unprecedented levels of efficiency, reliability, and energy conservation. For instance, AI systems will predict optimal machine calibration settings and dynamically adjust robotic operations, ensuring consistently high product quality. Additionally, AI-powered predictive analytics will streamline inventory management, reduce waste, and enhance overall resource utilization, thus driving significant cost savings and sustainable practices.

Through full automation, strategic IIoT integration, and AI-assisted optimization, Thor is poised to establish itself as a pioneering leader in intelligent manufacturing within the surge protective device industry, setting new benchmarks for innovation, efficiency, and quality.

4.Sustainability and Environmental Impact

Thor recognizes the critical importance of sustainability in contemporary manufacturing practices. The transition from manual processes to automated production is strategically aligned with Thor's commitment to reducing environmental impact. Automated production lines substantially reduce energy consumption through optimized operational efficiency and precision-driven processes, minimizing waste and conserving raw materials. By integrating IIoT and AI-driven analytics, Thor is positioned to further enhance resource utilization, significantly lower energy use, and reduce overall carbon emissions. Additionally, automated systems contribute to a noticeable decrease in material waste, ensuring that Thor's operations remain environmentally responsible. This commitment not only supports global sustainability goals but also strengthens Thor's brand as an environmentally conscious industry leader.