Since the start of 2025 and into 2026, The global electrical supply chain has seen unmatched instability. From mining constraints to market fluctuations, commodity prices have fundamentally shifted the economic baseline for electrical appliance manufacturers worldwide.

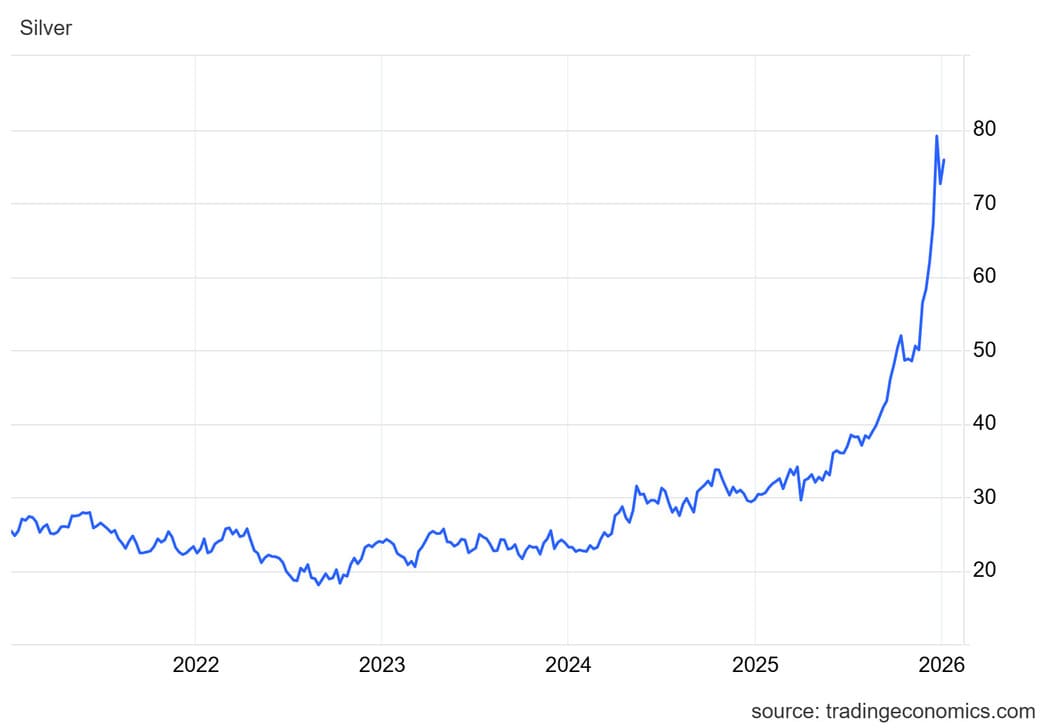

At Thor, we believe transparency is the foundation of trust. We will look past the marketing fluff and focus strictly on supply chain dynamics and material science. The reality is that an SPD is a safety-critical device, not a simple commodity. Its ability to divert massive surges and protect your assets is intrinsically sensitive to the quality and volume of base metals used in its construction.

As the markets for Copper, Silver, and Tin reach new highs, we want to explain exactly how these raw material trends impact the manufacturing—and the cost—of reliable electrical protection.

Latest Metal Market Trends

The international metal market is going through a turbulent phase with restrictions on supply and escalating demand. The volatility index for basic metals has reached record high levels for the period from the end of 2025 through early 2026, according to information released by the london metal exchange (LME).

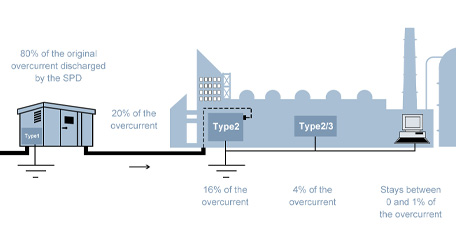

Copper, often viewed as the bellwether of the industrial economy, has seen prices skyrocket. The price surge is driven by the aggressive global push for electrification, EVs, and grid modernization, creating a structural deficit where mining output simply cannot keep pace with consumption. The chart below illustrates copper's upward trajectory, highlighting its significant role in powering modern infrastructure

Figure 1 - Copper price trend in five years (Source: tradingeconomics.com)

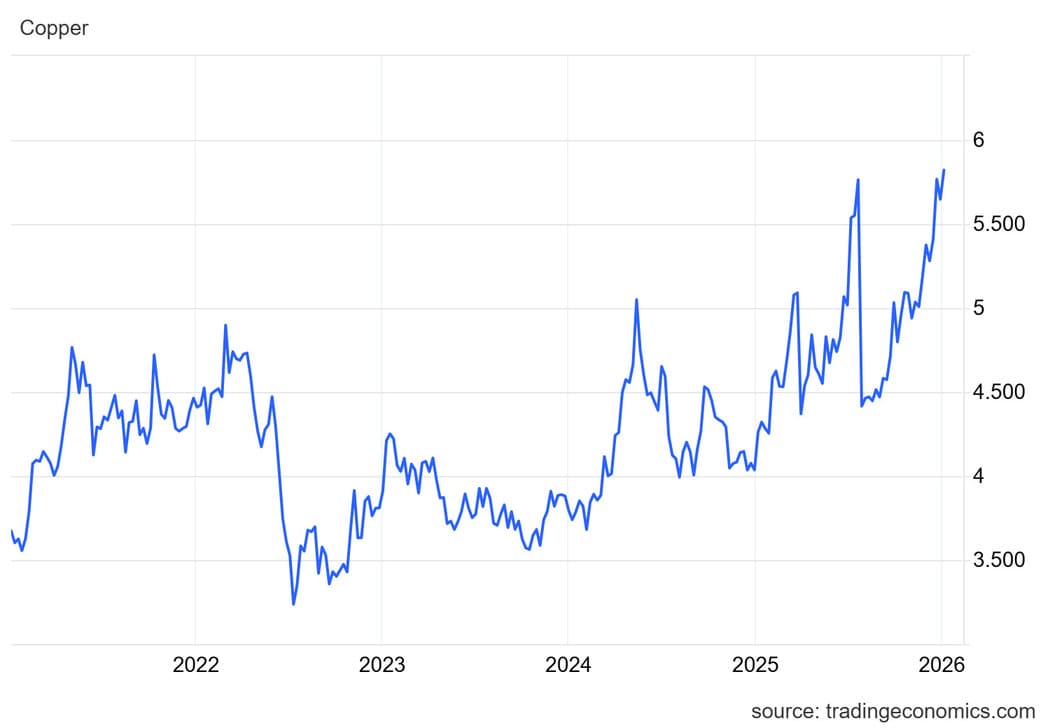

Silver is facing similar pressure. Beyond its value as a precious metal, silver’s critical role in the booming photovoltaic (solar energy) and high-end electronics sectors has drained global inventories to critical lows. As seen in the chart, silver’s value has climbed significantly, reflecting its increased demand across multiple high-tech industries.

Figure 2 - Silver price trend in five years (Source: tradingeconomics.com)

Tin, essential for soldering and connections, continues to suffer from supply chain fragility in major export regions, keeping prices elevated. The trend in the tin market underscores the broader supply chain challenges impacting electronic component manufacturing globally.

Figure 3 - Tin price trend in five years (Source: tradingeconomics.com)

For the manufacturing sector, this is not merely a temporary fluctuation but a new economic baseline. The cost of securing high-purity raw materials has risen sharply, directly impacting the production costs of component-heavy safety devices like SPDs.

What does this trend have to do with SPDs?

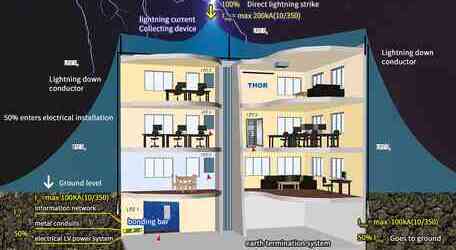

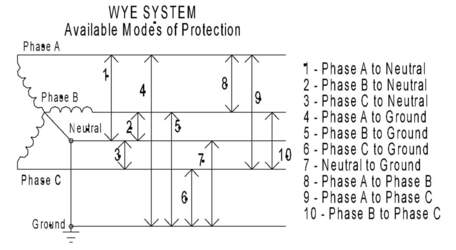

A Surge Protective Device (SPD) is a precision safety component designed to conduct high-energy currents to the ground instantaneously. The performance and safety of an SPD rely directly on the physical properties—specifically conductivity and thermal stability—of the metals used in its construction.

Here is a technical breakdown of how Copper, Silver, and Tin are utilized in our products and why maintaining material standards is critical despite rising costs:

1.Copper (Cu): Current Carrying Capacity & Impedance

Copper is the primary material used for internal busbars, wiring, and connection terminals within the SPD.

Figure 4 - High-purity copper busbars and terminals

To effectively limit overvoltage, the internal path of the SPD must have minimal impedance. As illustrated in Figure 4, we utilize high-purity electrolytic copper rather than cheaper brass alternatives to maximize electrical conductivity and manage the heat generated during a surge event without overheating the component.

Reducing the cross-sectional area of copper components or switching to brass alloys would lower manufacturing costs. However, this increases the internal resistance, leading to a higher Voltage Protection Level (Up) and higher temperature rise. We maintain our original copper specifications to ensure the device performs within IEC/UL safety limits.

2.Silver (Ag): Thermal Disconnection Mechanism

Silver is an essential component in the low-temperature solder alloys and contact points used in the SPD's thermal disconnect system.

Figure 5 - Silver-cladded thermal disconnect mechanism

Technical Function: The thermal disconnect is a safety mechanism designed to separate the metal oxide varistor (MOV) from the power source if it degrades or overheats. Silver is required here for its superior conductivity and oxidation resistance for a stable connection over years of service and it minimizes electrical arcing during the disconnection process.

Figure 5 shows the critical silver contact points integrated into our thermal disconnect system. We rely on silver’s superior conductivity and oxidation resistance to guarantee a stable, arc-free separation of the MOV during a thermal event.

The Cost Reality: Reducing silver content in solder alloys can compromise the reliability of the disconnect mechanism, resulting in potential risks of the device failing to disconnect safely during a thermal runaway event and even causing fire hazards. We continue to use specific silver-based alloys to guarantee functional safety.

3.Tin (Sn): Soldering Integrity and Assembly

Tin is the fundamental material for Printed Circuit Board Assembly (PCBA) and the plating of metal terminals.

Figure 6 - Internal assembly and solder joint integrity

Technical Function: High-quality tin plays a crucial role in maintaining the mechanical and electrical integrity of solder joints. SPDs often operate in industrial environments subject to vibration and thermal cycling.

Figure 6 displays the internal assembly where high-grade environmental tin plays a pivotal role in creating solder joints. By maintaining a high tin content, we ensure the device withstands harsh industrial vibrations and thermal cycling without the risk of solder cracking or connection failure.

The Cost Reality: As tin prices surge, utilizing recycled or lower-purity solder offers an easy path to cost reduction. Such materials, however, introduce contaminants that degrade the mechanical strength of the solder joints. Under the stress of electrical surges and panel vibrations, inferior joints are prone to cracking or rapid oxidation. We maintain our specification for high-purity tin to guarantee a robust connection that withstands harsh operating conditions.

Our operational response & pricing adjustment

At Thor, we have implemented lean manufacturing strategies to absorb initial market fluctuations internally. However, the sustained escalation in commodity costs requires a necessary commercial realignment.

Please note that these adjustments will not apply uniformly across our entire portfolio. The revised pricing reflects the specific material density of each model. High-capacity SPDs, which demand substantial volumes of Copper for busbars and Silver for arc-quenching mechanisms, will undergo a proportional cost update.

Conversely, models with lower metal content will experience a more moderate change. We aim to maintain a fair pricing structure that strictly mirrors the underlying material reality of each distinct product series.